MODULAR PRODUCTS

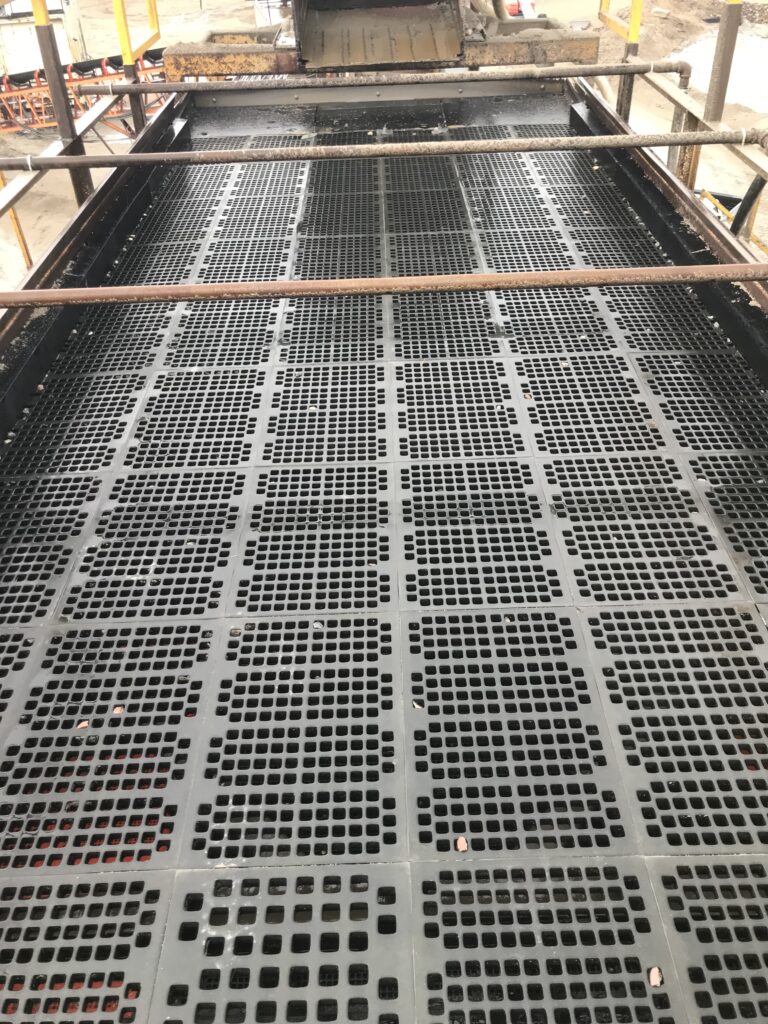

All of our modular systems come in a wide array of opening shapes and sizes and are drop-in replacements, eliminating the need for retrofitting your deck in order to use our products.

MODULAR PRODUCTS

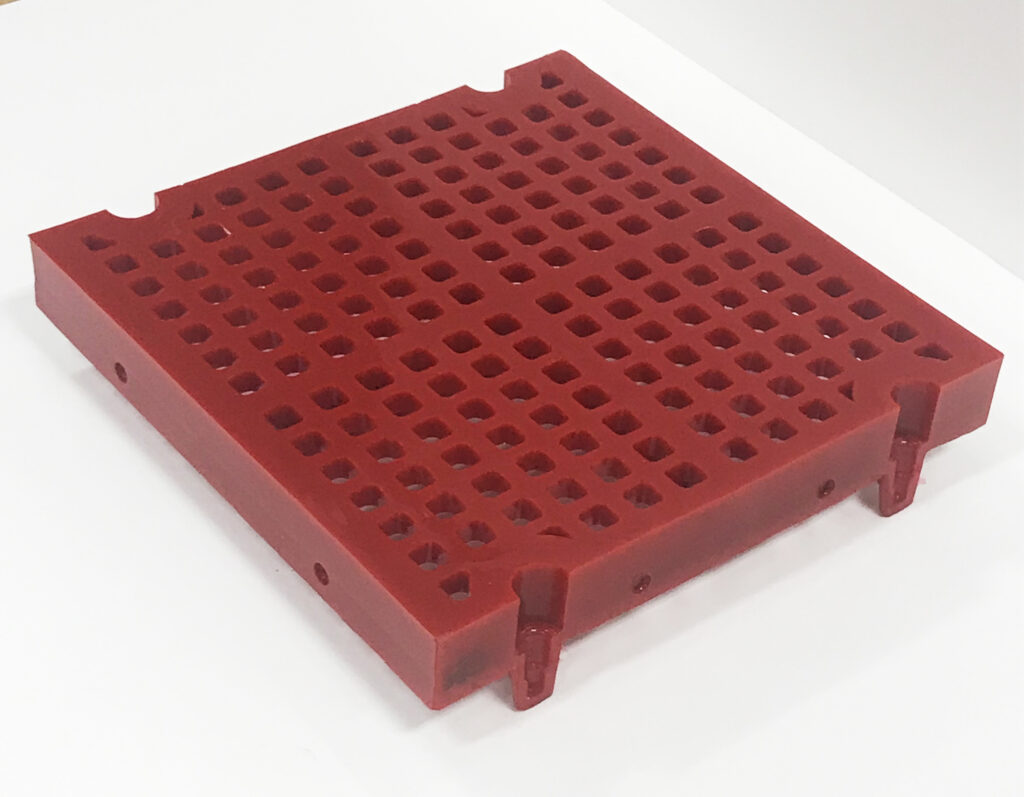

RSX MODULAR SYSTEM

- EASE OF INSTALLATION

- AFFORDABILITY

- BEST OVERALL DECK OPEN AREA

- SECONDARY SCREENING

- WASH SCREENS

- TERTIARY SCREENING

- MILL DISCHARGE

- Segmented snaps and 16” width combine to create extreme open area design.

- Stringers on 16” centers allow for over 30% more clearance

vs other competitive systems. - Standard panel size: 16.00” wide x 24.00” long. 12.00” wide x 24.00” long options are also available.

- Standard thickness: 1.50” and 2.00” but custom thicknesses are available to meet your needs.

WHY DID WE DESIGN THE RSX -16?

The RSX-16 Modular Screening system was derived from years of experience in the screening industry, learning and understanding what features hold the most value for our customers and what design pitfalls to avoid has enabled us to create the most innovative modular system on the market today.

Rockshield’s RSX – 16 was designed with three main objectives in mind.

This is the easiest and most intuitive to use no matter if you are a seasoned millwright or the new guy on the job.

The additional width of our 16″ wide panel allows customers to navigate the deck with ease.

• Standard width panel clearance = 10″; RSX-16 clearance = 14.50″

• The segmented snap system makes installing and uninstalling the panel easy and requires no special tools, pins, or fasteners.

• The tubular stringer system is extremely basic to install and maintain.

• Having wider panels also reduces the number of stringers required per deck which lowers stresses on the machine and increases bearing life.

This system allows us to exceed the open area capabilities of what is out there today enabling our customers to put more product on the ground without having to increase the size of their vibrating screens.

• Because of the extra wide panels we have fewer panels per the width of a deck, thus reducing the number of solid margins between panels allowing us to put openings in places other systems cannot.

• Using a segmented snap design we are able to bring openings out closer to the panels perimeter allowing us to fit more openings in our panel.

• Our additional width makes it possible to fit larger openings into our design in a more efficient manner.

We created a modular system that is cost effective to manufacture and sell it at a price point that fits any customers budget regardless if they have used rubber for years or are just looking to upgrade from wire media.

• Because of the wider design we require fewer panels per deck thus reducing our manufacturing costs by up to 30% over other competitive systems.

• The simplistic nature of our tubular stringer design allows us to use “off the shelf” structural steel which makes it cost effective and easy to source.

MODULAR PRODUCTS

CUTPOINT MODULAR SYSTEMS

- SCALPING

- SIZING

- WASHING

- TROMMEL/ROTARY SCREENS

- MILL DISCHARGE

- 1′ X 1′

- 1′ X 2′

- 1’X 4′

- CUSTOM SIZES AVAILABLE

- Custom-designed screen surface to fit the application: – Rigid: Impact resistant

- Available thicknesses from 1” to 3.50” overall

- Available opening sizes from .25” to 8”

- Available in all opening shapes (square, slotted, round, etc.)