A BETTER SOLUTION

INNOVATIVE WEAR COMPONENTS & SCREEN MEDIA FOR TODAY'S MINERAL PROCESSING & AGGREGATE INDUSTRIES

"PUT MORE ROCK ON THE GROUND"

ROCKSHIELD RUBBER COMPANY

APPLICATION-SPECIFIC SCREEN MEDIA & WEAR COMPONENTS

Rockshield Rubber Company is based in Milltown, Wisconsin. We specialize in the manufacture of custom rubber and polyurethane wear components used in the mining and aggregate industries. Our strength is designing and building application-specific screen media and wear components to meet the requirements of our end users. 40+ years of industry experience, combined with our proven synthetics technology, enables us to manufacture high-quality rubber and polyurethane products that will maximize your uptime while promoting safety and a “lowest cost per ton” approach to your business.

OUR PRODUCTS

AGGREGATE & MINING INDUSTRIES

INNOVATIVE WEAR COMPONENT SOLUTIONS

BROUGHT TO YOU BY EXPERT-LEVEL, INDUSTRY PROFESSIONALS

OUR MATERIALS

SERVING THE MINING & AGGREGATE INDUSTRIES

ALL ENCOMPASSING SOLUTIONS: THE ONLY COMPANY TO PROVIDE ALL COMPETITIVE MODULAR MEDIA SYSTEMS IN BOTH RUBBER & URETHANE

POLYURETHANE

RUBBER

SEAMLESS MODULAR SOLUTIONS

WHAT WE DO

SOLVING

YOUR LATEST BOTTLENECK

We have expertise in developing custom solutions for mining and aggregate industries that help customers evaluate process flow and media requirements to maximize output.

LOWERING

YOUR COST OF OWNERSHIP

More durable wear parts mean more uptime, which translates into more on our customer’s bottom line. Our long-lasting solutions mean you spend less on replacement costs and avoid the downtime hassles that come with less durable materials.

PROVIDING

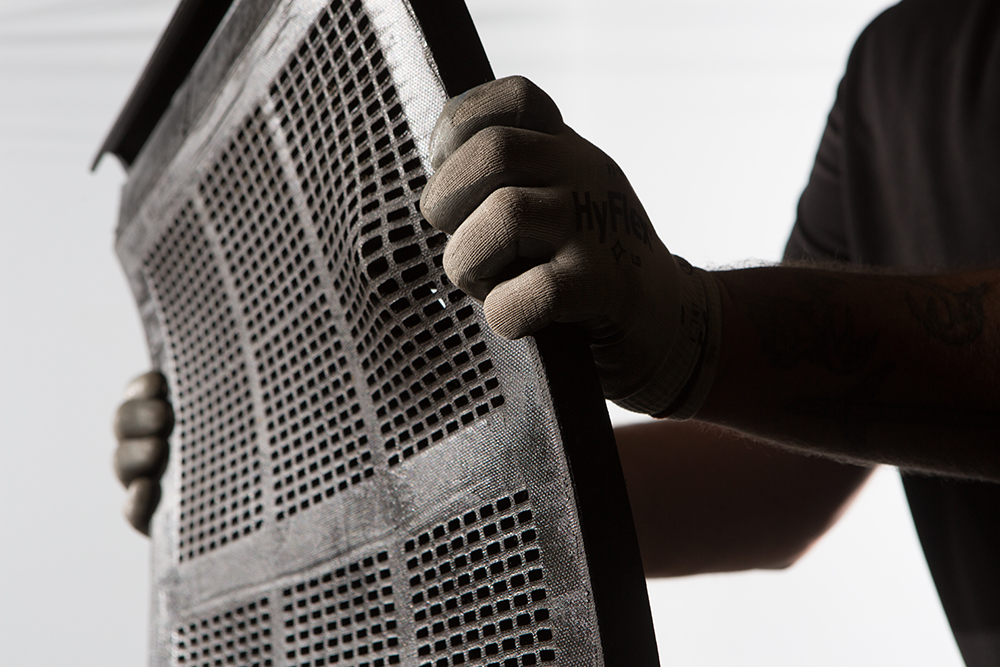

EASE OF MAINTENANCE

We want to reduce your downtime so you can put more material on the ground. Our products are designed with the customer and maximum ease of maintenance in mind. Our products are

drop-in replacements, reducing or eliminating the need for costly retrofits, and can be used interchangeably with your existing components.

SUCESSFUL SYNTHETIC SCREEN MEDIA SOLUTIONS

HOW WE HELP

At Rockshield Rubber Company, you will get personalized support and an expert-level, customized solution. We’ll be with you every step of the way. That’s our promise.

We can get you a quote back in 24 hours. You’ll talk to the right person right away.

We have the expertise to help you spec the right solutions into your project.

We can help you pinpoint issues with wear and make recommendations to increase your uptime.

FEATURED PRODUCT

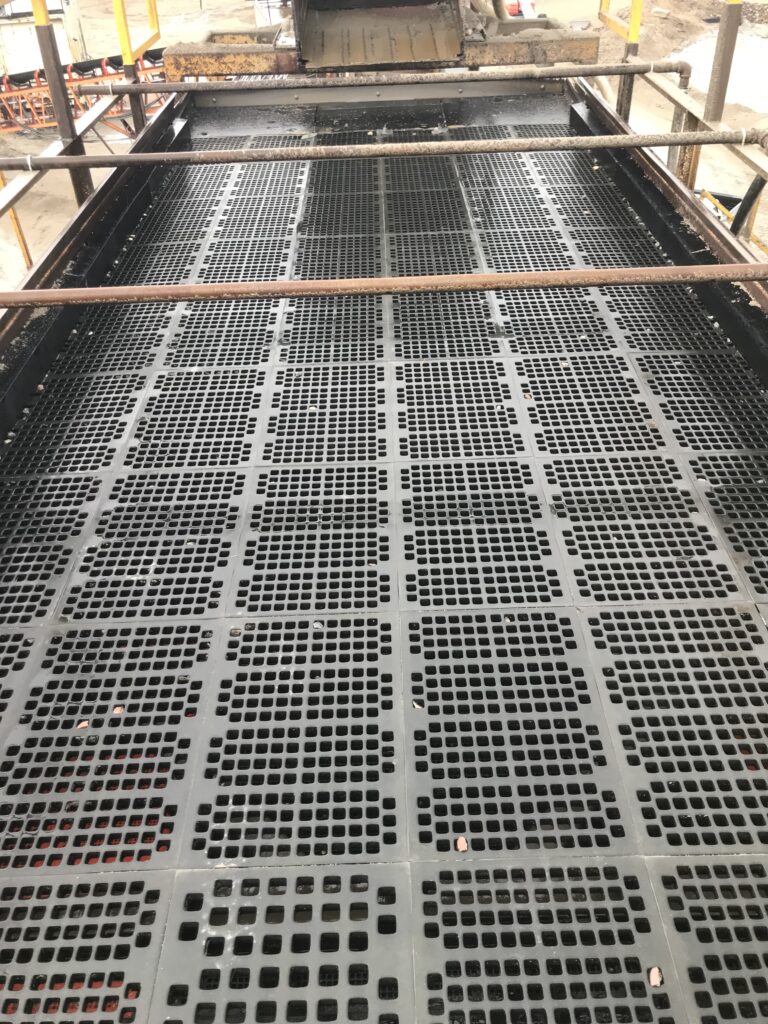

RSX-16 MODULAR SYSTEM

SCREENING HASN'T CHANGED MUCH IN 50 YEARS.

UNTIL NOW...…

RockShield Rubber Company’s RSX-16 is unlike any system you’ve seen before. We analyzed the challenges of other modular systems and innovated a new design that is easy to install, gives you the best open area in the industry, and saves you money. A wider panel decreases the solid margins down the deck, increasing the overall deck open area. The 16” width of the RSX-16 makes it easier to navigate the system during changeouts. Our segmented snaps mean no special tools needed to install or uninstall. And, the simple stringer system with the snap feature on the side keeps the snap out of the flow of material.